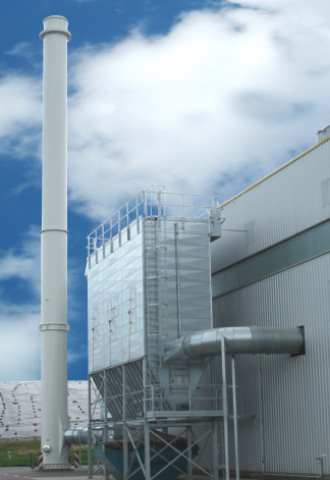

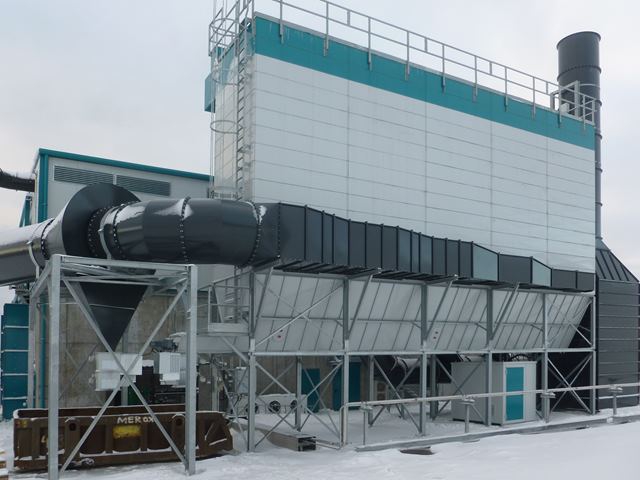

R&R BETH bag filters are used for cleaning process-air and exhaust gas streams with a wide variety of pollutant loads.

Depending on the application, R&R BETH bag filter systems can be operated in a continuous cleaning process with compressed air pulses in "online/offline mode", with rinsing air in "offline mode" of individual filter chambers or in a discontinuous cleaning process with vibration cleaning.

A very large selection of technical filter media, a process-oriented design of the inflow of the raw gas and a robust construction allow R&R BETH bag filter systems to be used in the harsh environment of almost all industrial sectors.

The separation of dusts, ashes and smaller lump materials enables reliable purification of the process air up to 250 °C and additionally enables an almost quantitative recovery of particulate and dusty valuable materials.

By using a wide variety of additives, additional inorganics and organics including dioxins/furans, PAH and PCB compounds as well as heavy metals can be separated.

Environmental regulations are complied with reliably and permanently while maintaining the specified emission values and taking into account a wide range of upstream production processes.

Different designs, pressure-resistant and pressure-shock-resistant housings and substructures with static verification enable optimal adaptation to each individual application.

For further information please contact us here...

FUNCTIONAL PRINCIPLE "ONLINE - CLEANING"

With so-called "online method", puring takes place during the ongoing filtration process. The raw gas enters the lower part of the filter housing and is separated into clean gas and dust at the filter bags.

FUNCTIONAL PRINCIPLE "OFFLINE - CLEANING"

The filter is a chamber construction that can be isolated on both, the raw gas and the clean gas side. The raw gas enters the lower part of the filter body through the raw gas channel and separated into clean gas and dust at the filter bags.

To clean the filter bags, one filter unit (of the filter housing divided by partitions) is taken out of operation on the clean gas side by a pneumatically operated poppet valve. Each row of filter bags (of the filter unit taken out of filtration) is backwashed through the nozzle tubes arranged above the filter bags. For this purpose, compressed air tanks with integrated diaphragm valves and encapsulated solenoid valves are arranged in the filter head.

The solenoid valves are operated periodically by an electronic monitoring device. The compessed air escaping from the storage tank is led into the filter bags of the disconnected row via the nozzle tubes and jet pipe injectors assigned to the individual filter bags. Due to the injector effect, the compressed-airpulse sweeps along the clean gas. The mixture of compressed air and clean gas abruptly and thoroughly backflushes the filter bags.

After the entire row of filter bags is cleaned and a preset time lag (depending on the specific task) has passed, the filter unit is reconnected to the volume flow and set back into foltration mode by opening the poppet valve. After that, the next filtration unit is removed from the filtration process for cleaning. Additionally, evry filter unit can be seald off from both the raw gas and the clean gas side for maintenance work.

For further information please contact us here...

Filtration phase

Through the nozzle tubes arranged above the filter bags, each row of filter bags is cleaned separately with compressed air pulses. For this purpose, compressed air reservoirs with integrated diaphragm valves are arranged in the filter head. These are operated by fully enclosed pilot solenoid valves. The solenoid valves are controlled periodically by an electronic control unit.

Cleaning phase

The compressed air escaping from the compressed air reservoir is directed into the filter bags via nozzle tubes and the jet pipe injectors located directly above the filter bags. Due to the injector effect, the compressed air jet entrains secondary air from the clean gas section.

Due to the effective way of cleaning, even filter bags with a length of up to 7,000 mm can be cleaned safely.